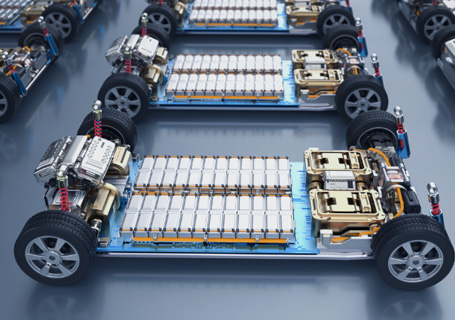

Product supply

We provide high quality products to meet the material requirements of automotive manufacturers. Our products can be ensured to meet relevant standards and requirements, as well as supporting continuous supply chain.

Technical support

We have a professional technical team that keeps up to date with professional knowledge of relevant materials and provides technical advice and support.

Quality control

We strictly control the quality of our products and provide relevant quality assurance. We are equipped with advanced laboratory facilities and quality testing equipment to ensure that our products meet the requirements and standards of our customers.

After-sales service

We provide comprehensive after-sales service, including guidance on the use of our products, technical training and after-sales support. We are committed to building long-term relationships with our customers and providing ongoing support and service.