Fluorine Promotes PVDF Resins in Multiple Applications

I). Application areas of PVDF resin

1、Anti-corrosion materials: powder coating, lining pipes, joints, pumps, valves, plates, etc;

2, aging-resistant materials: surface powder layer of the composite film;

3, electrical and electronic materials: wire wrapping, piezoelectric film, thermoelectric film, rechargeable battery materials;

4, Others: fishing line, monofilament, hollow wire;

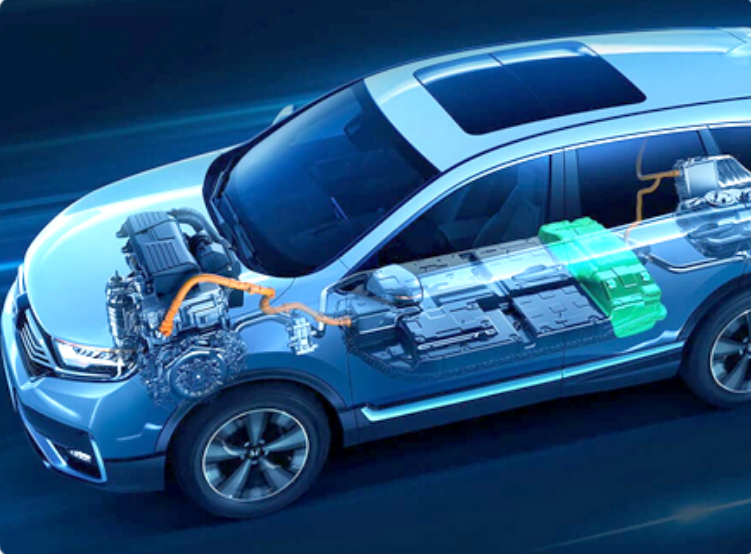

II). PVDF in lithium battery applications

1, lithium battery cathode binder

2, lithium battery separator

III). Market Outlook

In 2022, by the growing demand of new energy vehicles, photovoltaic, 5G, Li-ion battery market and other industries, the supply and demand of PVDF and its upstream main raw material R142b is tight, while the new capacity expansion time is long, and the product technology barriers are high. Therefore, the short-term supply can not be effectively mitigated. Eventually the price is all the way up.With the rapid rise of the Li-ion battery market and the increasingly stringent wastewater discharge policy, the future market potential of PVDF is huge, and major manufacturers have announced the expansion or new production capacity. 2022 the second half of the year, with the gradual release of new production capacity, and the cooling of the new energy industry, the PVDF market began to downward trend, the price of PVDF began to return to rationality.

In the global "dual-carbon" goal, to promote the development of a clean and low-carbon energy system in the context of the times, photovoltaic power generation and power cars in the world will be in a period of rapid development, and the demand for PVDF in lithium batteries will continue to maintain a high rate of growth.